Industrial 3D-Printer

Project for Mighty Buildings (Mexico, Monterrey city), 2020–2022

Tilda Publishing

A control system has been developed for a compact industrial 3D printer to print functional composite parts with high speed and accuracy. The system includes built-in ventilation and heating, reduces maintenance time, and minimizes human error through automation. The hardware platform is Mitsubishi Electric iQ-R, and the industrial assembly is made according to the UL508A standard. The project included circuit design, assembly coordination, and commissioning.

Hardware platform — Mitsubishi Electric iQ-R with Motion CPU, G-code control using built-in controller tools. Electrical diagrams developed in SolidWorks Electrical.

The industrial panel assembly complies with UL508A and is UL-inspected.

The industrial panel assembly complies with UL508A and is UL-inspected.

Maintaining the set temperature in the printing area using the built-in heating system;

Built-in ventilation with filtration of harmful vapors during curing.;

Rapid delivery of ready-made solutions (Mighty Kit System).

Automation of production with minimization of human influence;

High printing speed and accuracy;

System features

Reduced maintenance time thanks to wear-resistant components and a safety alert system;

2022-2024

Customer: MightyBuildings, LTD (Mexico, Monterrey city)

Solution: A compact and high-precision control system has been developed for an industrial

3D printer for the additive manufacturing of functional and structural parts with complex geometries from photo-curing composite materials with continuous fiber reinforcement.

3D printer for the additive manufacturing of functional and structural parts with complex geometries from photo-curing composite materials with continuous fiber reinforcement.

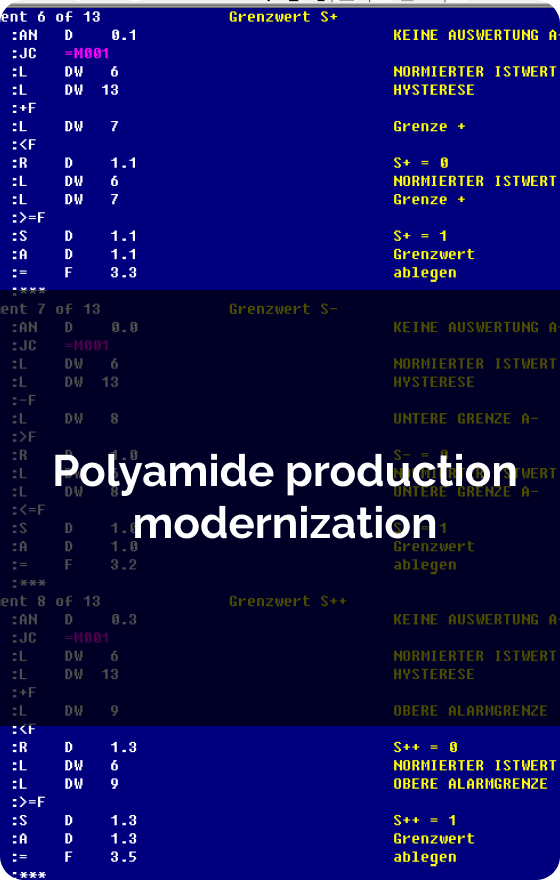

Circuit diagram of an industrial 3D printer

Industrial 3D printer

A control system has been developed for a compact industrial 3D printer for printing functional composite parts with high speed and accuracy. The system includes built-in ventilation and heating, reduces maintenance time, and minimizes human error through automation. The hardware platform is Mitsubishi Electric iQ-R, and the industrial assembly is made according to the UL508A standard. The project included circuit design, assembly coordination, and commissioning.

Hardware platform — Mitsubishi Electric iQ-R with Motion CPU, G-code control using built-in controller tools. Electrical diagrams were developed in SolidWorks Electrical, industrial panel assembly was performed in accordance with UL508A and confirmed by UL inspection.

Maintaining the set temperature in the printing area using a built-in heating system;

Built-in ventilation with filtration of harmful vapors during curing;

Scheme of an industrial 3D printer

Fast delivery of ready-made solutions (Mighty Kit System).

High printing speed and accuracy;

System features

Automation of production with minimization of human influence;

Reduced maintenance time thanks to wear-resistant components and a safety alert system;

Implementation year: 2022-2024

Customer: MightyBuildings, Mexico

(Monterrey)

(Monterrey)

Solution:

A compact and high-precision control system has been developed for an industrial 3D printer for the additive manufacturing of functional and structural parts with complex geometries from photo-curing composite materials with continuous fiber reinforcement.

A compact and high-precision control system has been developed for an industrial 3D printer for the additive manufacturing of functional and structural parts with complex geometries from photo-curing composite materials with continuous fiber reinforcement.

Industrial 3D printer

Projects

Contact us — call us, send us an email, or fill out the feedback form

Still have questions?

Contact us — call us, send us an email, or fill out the feedback form

Still have questions?

By clicking the button, you consent to the processing of your personal data and agree to the privacy policy.