Polyacrylamide Production Modernization

Tilda Publishing

Due to the tight deadlines for installation and commissioning work (7 days), the project required careful planning and coordination. The work was completed successfully, without downtime or production losses. As a result, the customer received a modern, efficient, and reliable control system.

Year of implementation - 2017

Customer: Solenis, Perm

As part of the project, the polyacrylamide production automation system was upgraded by replacing two Siemens S5 controllers with one Siemens S7-400 while fully preserving the original logic and software structure. The operator panel systems were updated to WinCC V13. Installation and commissioning work was completed within 7 days. The customer received a modern, reliable, and compliant system.

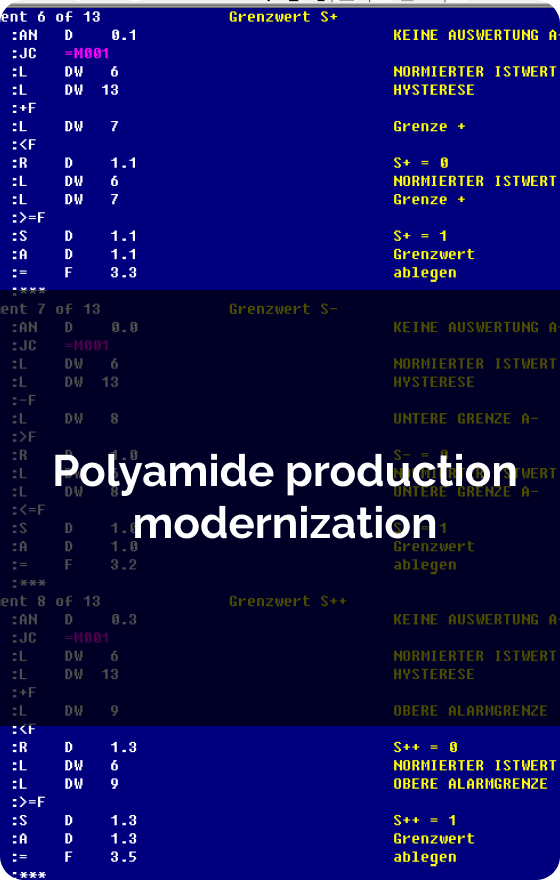

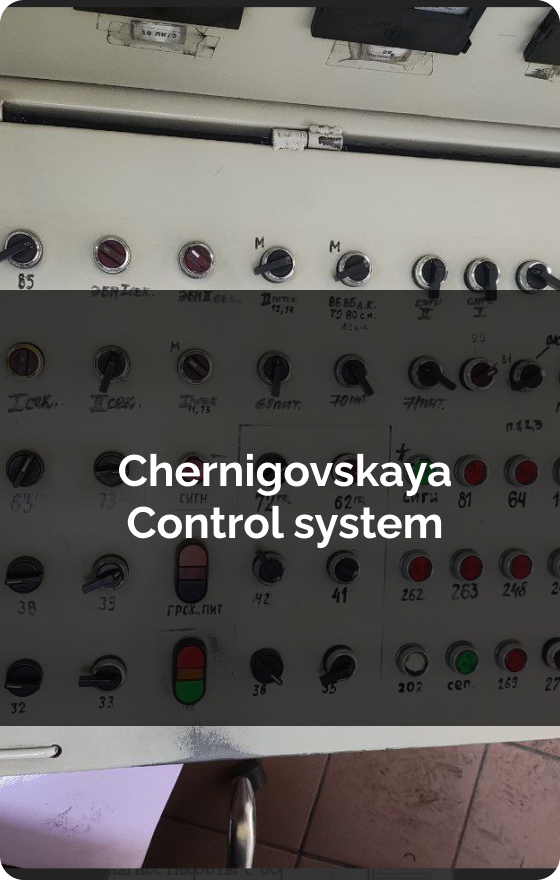

Task: The project to modernize the polyacrylamide powder production control system involved replacing two outdated Siemens S5 PLCs with a single modern Siemens S7-400 controller. The original automated system included two S5 PLCs, 20 distributed DP stations, two operator panel systems, and approximately 2,000 signals. The customer's key requirement was to fully preserve the functionality, logic, and structure of the software, which required detailed analysis and manual development of all functions due to the complexity of the original code.

Due to the tight deadlines for installation and commissioning work (7 days), the project required careful planning and coordination. The work was completed successfully, without downtime or production losses. As a result, the customer received a modern, efficient, and reliable control system.

Year of implementation: 2017

Customer: Solenis, Perm

As part of the project, the polyacrylamide production automation system was upgraded by replacing two Siemens S5 controllers with one Siemens S7-400 while fully preserving the original logic and software structure. The operator panel systems were updated to WinCC V13. Installation and commissioning work was completed within 7 days. The customer received a modern, reliable, and compliant system.

Task: The project to modernize the polyacrylamide powder production control system involved replacing two outdated Siemens S5 PLCs with a single modern Siemens S7-400 controller. The original automated system included two S5 PLCs, 20 distributed DP stations, two operator panel systems, and approximately 2,000 signals. The customer's key requirement was to fully preserve the functionality, logic, and structure of the software, which required detailed analysis and manual development of all functions due to the complexity of the original code.

Projects

Contact us — call us, send us an email, or fill out the feedback form

Still have questions?

Contact us — call us, send us an email, or fill out the feedback form

Still have questions?

By clicking the button, you consent to the processing of your personal data and agree to the privacy policy.